CS-8030H is a full-automatic wire cutting and stripping machine, suitable for processing 0.5~30mm2 cable wires, within 8 wires can be processed, it adopts the belt feeding method instead of the traditional wheel feeding, which improves the precision of feeding, and at the same time, there is no indentation on the surface of the wire skin. This machine can be equipped with optional automatic take-up device and code printer, the take-up device is mainly used for processing long wires, which can put the wires into the take-up tray flatly and straightly; the code printer can spray the code at any specified position of the wires, the color of the characters of the code printer and the color of the characters of the black and white can be selected.

Functions:

1. Stripping the Sheath: The core function of the 30-square sheath wire stripping machine is to strip the outer sheath of the cable, exposing the internal metal conductor. It is designed for cables with a specification of 30 square millimeters, precisely removing the outer sheath without damaging the inner core wire.

2. Adjustable Stripping Length: The operator can set the desired stripping length. This function allows for flexible adjustment based on specific needs, making it adaptable to different application scenarios.

3. Automatic Feeding and Cutting: The stripping machine typically comes with an automatic feeding system, which automatically feeds the cable and precisely performs the sheath stripping, reducing manual intervention and ensuring production efficiency.

4. Precise Control: Equipped with high-precision tools and control systems, the machine ensures the accuracy of the stripping process, avoiding damage to the internal conductors. It can adapt to different cable materials by adjusting pressure and cutting depth.

5. Adapts to Different Sheath Materials: The machine is capable of stripping various types of sheath materials, such as PVC, PE, rubber, etc., offering strong adaptability.

6. Increased Production Efficiency: The equipment uses a high-efficiency electric drive system, allowing for fast and stable large-scale cable stripping operations, making it suitable for industrial production environments.

7. Waste Collection: The stripping machine usually comes with a waste collection device that automatically collects the stripped sheath and other waste materials, reducing clutter in the working area.

8. Safety Protection Features: The equipment is equipped with safety protection devices, such as emergency stop buttons and safety shields, ensuring the operator’s safety.

Features:

1. This machine is a fully automatic wire cutting and stripping machine, suitable for processing cables from 0.5 to 30 mm².

2. It uses a belt feeding system instead of the traditional wheel feeding method, improving feeding accuracy and ensuring no pressure marks on the wire surface.

3. The machine can be optionally equipped with an automatic winding device and a coding machine. The winding device is primarily used for processing long cables and can place the wire neatly into the winding tray.

| Model | CS-8030H |

| Available Wire | Round sheathed cable |

| Conductor Cross-Section | 1-30mm² |

| Inner Core Numbers | Within 8 cores |

| Cutting Length | 1-99999mm |

| Cutting Length Tolerances | ≤(0.002*L) mm |

| Jacket Stripping Length | Head 10-120mm; Tail 10-80mm |

| Inner Core Stripping Length | Head 1-50mm; Tail 1-50mm |

| Conduit Diameter | φ16mm |

| Production Rate | One cores wire, 2300pcs/h |

| Multi cores cable, 800pcs/h | |

| Display Screen | 7 inch touch screen |

| Wire Feed Method | Belt feeding |

| Drive Method | 16 wheels drive |

| Power Supply | 220V/110V |

| Power | 1200W |

| Weight | 115kg |

| Dimensions | 85*54*63cm |

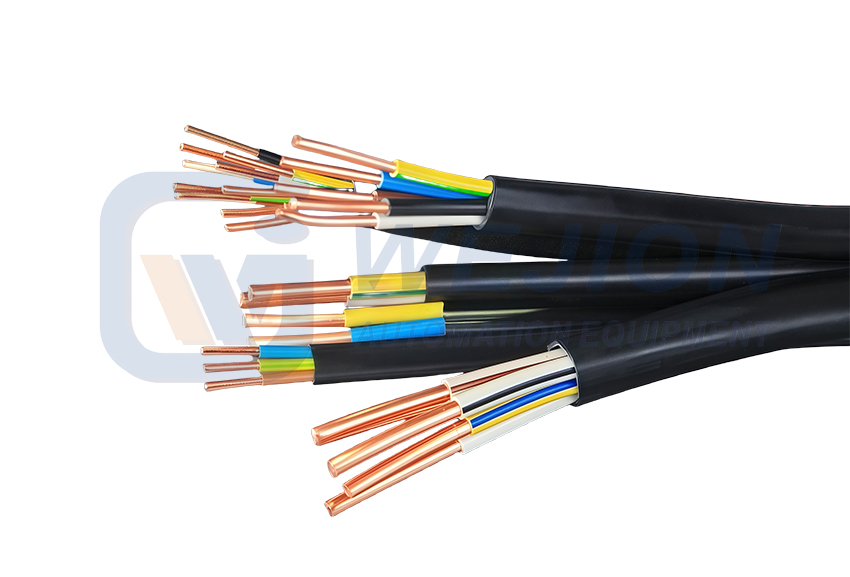

Multi-core cables consist of multiple insulated conductors bundled under a single sheath. They are widely used where flexibility, space efficiency, or complex signal/power transmission is required.

Motor Control: Connects PLCs (Programmable Logic Controllers) to servo motors, VFDs (Variable Frequency Drives), and actuators.

Sensor Networks: Transmits signals from pressure/temperature sensors (e.g., 4–20 mA or RS-485 communication).

Robotics: Powers joints and control units in robotic arms (high-flex designs with PUR/PVC insulation).

Temporary Power Supplies: Used in construction sites or events (e.g., rubber-insulated multi-core cables like H07RN-F).

Subpanel Wiring: Feeds secondary distribution boards in buildings.

Three-Phase Systems: Multi-core cables (e.g., 4-core or 5-core) distribute balanced loads in 400V industrial setups.

Ethernet Cables: Shielded multi-core pairs (Cat5e/Cat6) for LAN networks.

Telecom Infrastructure: Fiber-optic multi-core cables for backbone networks.

Audio/Video Systems:

Multicore audio cables (e.g., 12–24 cores) for studio mixing consoles.

SDI/HDMI cables with multiple coaxial cores for broadcast equipment.

Automotive Wiring Harnesses: Powers ECUs (Engine Control Units), infotainment systems, and lighting (thin multi-core strands).

Aerospace: Lightweight, fire-resistant multi-core cables for avionics (e.g., MIL-SPEC standards).

Railways: Supplies control circuits, lighting, and signals in trains (BS6853 compliant for fire safety).

Solar Farms: Multi-core PV cables connect panels to combiner boxes (UV-resistant insulation).

Wind Turbines: Dynamic cables with multiple cores for pitch control and sensors (high-flex, oil-resistant).

Patient Monitoring: Multi-core cables for ECG machines, MRI systems, and ultrasound devices (shielded to reduce EMI).

Surgical Tools: Supplies power and signals to endoscopic/laser equipment.

Shipboard Wiring: Water-resistant multi-core cables (e.g., IEC 60092 standards) for navigation and propulsion systems.

Subsea Applications: Oil/gas rigs use armored multi-core cables for ROVs (Remotely Operated Vehicles).

Appliance Wiring: Inside washing machines, refrigerators, and AC units.

USB/Type-C Cables: Multi-core designs for power delivery and data transfer.

Conductor Types:

Copper: Standard for most applications (stranded for flexibility).

Tinned Copper: For marine/outdoor use (corrosion-resistant).

Insulation Materials:

PVC: General-purpose, cost-effective.

PUR (Polyurethane): Abrasion-resistant for robotics.

Silicone/Rubber: High-temperature/flexibility (e.g., stage lighting).

Shielding:

Foil/braided shields for EMI protection (e.g., in data/medical cables).

Standards:

UL/CSA: North America (e.g., UL AWM style).

IEC/EN: Europe (e.g., H05V-K, H07RN-F).

Military: MIL-DTL-27500 for aerospace.

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to sales@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions