The CS-B95 wire stripping machine is a professional automated equipment designed for processing wires with cross-sections ranging from 1.5-95mm², suitable for stripping insulation from various conductors including copper and aluminum. Featuring a high-precision servo control system and adaptive blade pressure adjustment, it ensures precise stripping without conductor damage.

CS-B95 Large Cable Computer Stripping Machine (all-electric, no air source required) is a high-performance, intelligent stripping equipment designed for processing large-section 95 square millimeter cables, suitable for precision stripping operations of various cables. It adopts advanced control systems and efficient drive technology, is easy to operate and has high stability, and is widely used in power, communications, new energy vehicle wiring harnesses, medical manufacturing and other industries

Functions & Features

1. Widely applicable wires

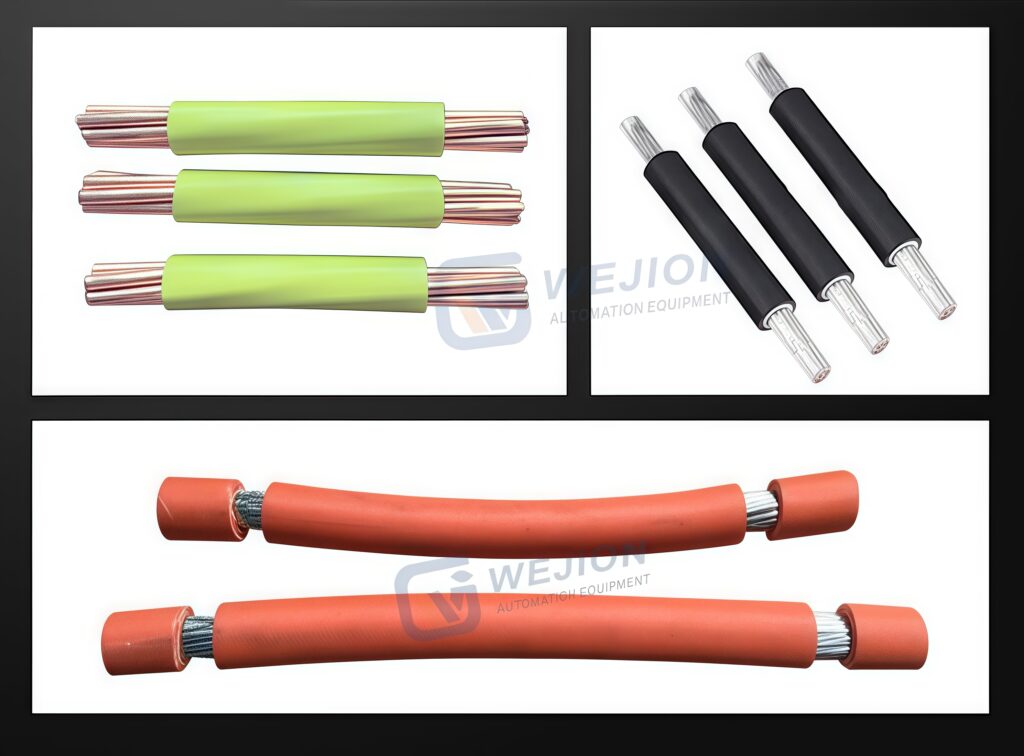

* Suitable for multi-strand copper wires, coaxial cables, sheathed cables and other types of cables, with strong adaptability and can meet the needs of various industries.

2. Independent research and development and patented technology

* This product is independently developed and has intellectual property patent procedures, which ensures the innovation and uniqueness of the equipment.

* Equipped with a 7-inch color touch screen, combined with a high-speed motion control system, it simplifies the operation process, making the equipment more intuitive and easy to operate.

* High stability, suitable for long-term high-load operation, ensuring efficient production.

3. 12 feeding wheel groups and belt feeding system

*12 feeding wheel groups and belt feeding system are used to provide a larger contact area, ensuring stable feeding and precise control of the cable during the stripping process without indentation or damage.

*The belt feeding system helps to accurately feed the wire and improve the processing quality, especially suitable for processing cables with large cross-sections.

4. Automatic adjustment of the inlet and outlet wheels

*The clamping force of the inlet and outlet wheels can be directly adjusted by the program, without manual adjustment, saving time for manual adjustment and avoiding human errors.

*Automatic lifting function of the outlet wheel: When stripping the wire head, the outlet wheel is automatically lifted to avoid contact with the cable, increase the stripping length range, and improve the stripping accuracy.

*The lifting height of the outlet wheel can be set by the program to flexibly adapt to different cable types and stripping requirements.

5. Large-capacity memory

*Equipped with a large-capacity memory, it can save 160 sets of parameters at the same time, which is convenient for processing and switching of different cables and improving production efficiency.

* Operators can quickly select appropriate program settings according to the processing requirements of different cables to reduce switching time.

6. Electric jump tube and long stripping function

* Electric jump tube function: supports free setting of the stripping length of the rear wheel, so that the stripping length of the cable can be adjusted more flexibly.

* The up and down jump distance is adjustable, which increases the stripping range, especially when processing longer cables, which can effectively increase work efficiency.

7. Fully electric drive, air source-free design

* The machine is completely driven by a motor and adopts a screw rod upper and lower pressure wheel system. No air source is required, which greatly reduces the dependence on the air source and improves the versatility and reliability of the equipment.

* The full electric design makes the equipment low in maintenance cost and more environmentally friendly and energy-saving to use.

8. Additional functions can be added

* The wire splitting jig and the scratching jig can be added to enable the equipment to meet special processing requirements and adapt to more complex cable processing tasks.

* Support the installation of inkjet printers, which can print information such as cable identification and production batches, facilitating product traceability and management.

| Model | CS-B95 |

| Display | 7-inch color touch screen PLC |

| Memory function | up to 200 groups of stored programs |

| Applicable wire diameter | multi-stranded copper wire, coaxial cable, sheathed wire, etc. |

| Driving mode | twelve-wheel drive |

| Applicable core area | 1.5-95mm² (sheathed wire OD 20.5mm) Blade material: imported high-speed stee |

| Max. diameter of conduit: | ø22mm, ø20mm, ø16mm, ø12mm, ø8mm |

| Working voltage | 220V/50Hz |

| Cutting length range | 0-999 meters |

| Rated power | 800W |

| Stripping length | full stripping wire head 0-300mm, wire tail 0-160mm |

| Machine dimensions | 700 * 640 * 480mm |

| Minimum length of glue | 50mm |

| Weight | about 135kg |

| Cutting tolerance: | ± (0.002mm * L) (L indicates the cutting length) |

| Stripping speed | 700-1,000 pieces/hour (according to the wire and set) |

| Model | CS-B95 |

|---|---|

| Display | 7-inch color touch screen PLC |

| Memory function | up to 200 groups of stored programs |

| Applicable wire diameter | multi-stranded copper wire, coaxial cable, sheathed wire, etc. |

| Driving mode | twelve-wheel drive |

| Applicable core area | 1.5-95mm² (sheathed wire OD 20.5mm) |

| Max. diameter of conduit | ø22mm, ø20mm, ø16mm, ø12mm, ø8mm |

| Working voltage | 220V/50Hz |

| Cutting length range | 0-999 meters |

| Rated power | 800W |

| Stripping length | full stripping wire head 0-300mm, wire tail 0-160mm |

| Machine dimensions | 70 * 64* 48cm |

| Minimum length of glue | 50mm |

| Weight | about 135kg |

| Cutting tolerance | ± (0.002mm * L) (L indicates the cutting length) |

| Stripping speed | 700-1,000 pieces/hour (according to the wire and set) |

Heavy Machinery & Equipment: Used to power large motors, compressors, and industrial machines requiring high current.

Manufacturing Plants: Supplies electricity to production lines, CNC machines, and welding systems.

Mining Operations: Powers drilling rigs, conveyor belts, and heavy-duty mining equipment due to its high current capacity.

Substations & Switchgear: Acts as feeder cables between transformers and distribution panels.

Underground Power Networks: Used in urban areas where overhead lines are impractical.

High-Capacity Circuits: Suitable for long-distance power transmission with minimal voltage drop.

High-Rise Buildings: Supplies electricity to main distribution boards (MDBs) and riser systems.

Shopping Malls & Hospitals: Powers centralized HVAC systems, elevators, and backup generators.

Data Centers: Provides reliable high-current connections for server racks and cooling systems.

Solar Farms: Connects solar inverters to the grid due to its ability to handle high DC/AC currents.

Wind Turbines: Used in power collection systems to transfer energy from turbines to substations.

Railway Electrification: Powers overhead catenary systems or third-rail systems in metro/subway networks.

Airports & Ports: Supplies electricity to runway lighting, cargo handling systems, and ship-to-shore power.

Oil & Gas Facilities: Used in refineries and offshore platforms due to resistance to harsh environments (if armored or insulated).

Temporary Power for Events: Deployed in concerts, exhibitions, and large-scale outdoor events requiring high power.

High Current Capacity: Can typically carry 200–250A (depending on insulation and installation method).

Durability: Often armored (SWA) or insulated (XLPE/PVC) for mechanical and thermal protection.

Flexibility: Available in stranded copper or aluminum, balancing cost and conductivity.

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to sales@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions