CS-8120 heavy-duty cable processing tool handles large 120mm² power cables with integrated cutting and stripping functions. It features hardened steel blades for clean cuts and adjustable stripping mechanisms to remove insulation layers precisely without damaging copper/aluminum conductors. The machine works with various cable types (PVC, XLPE, rubber) and offers both manual and automated operation options. Ideal for electrical installations and industrial maintenance, it ensures fast, safe, and consistent cable preparation for terminations, outperforming manual methods in efficiency. Safety features include blade guards and overload protection, with optional accessories for armored cables.

Functions & Features

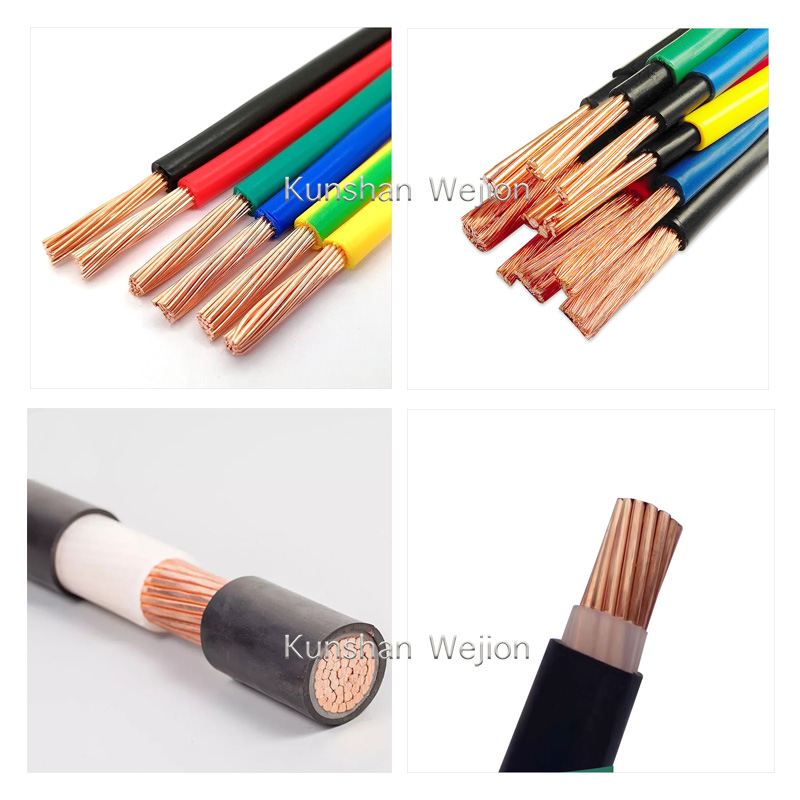

1. Wide range of applications:

* Suitable for cables and wires with a maximum cross-section of 120 square millimeters, and can handle various types of cables, including copper wire, aluminum wire, single-core, multi-core cables, etc.

* Can handle cables with different outer diameters and insulation thicknesses, adapting to diverse industrial needs.

2. 7-inch true color touch screen operation interface:

* Equipped with a 7-inch true color touch screen, the interface is intuitive, the display is clear, and the equipment operation status can be monitored in real time.

* Users can easily set the equipment’s working parameters, such as stripping length, stripping depth, speed, etc. through the touch screen, which is easy to operate and reduces the complexity of traditional physical button operations.

Supports multiple language interfaces for convenient international operation.

3. Automatic control system:

* Adopts high-performance PLC (programmable logic controller) control system to ensure stable equipment operation, and can automatically adjust the working status according to the set parameters to reduce manual intervention.

* High degree of automation, can achieve automatic feeding, automatic stripping, automatic material withdrawal, etc., to improve work efficiency.

4. Precision stripping function:

*Using precision tools and high-precision transmission system, it can accurately strip the insulation material of the outer layer of the cable to avoid damage to the internal metal wire core.

*Parameters such as stripping depth and length can be adjusted according to actual needs to ensure accurate stripping and ensure the quality of the cable.

5. Efficient working capacity

*The 120 square wire stripping machine has strong processing capacity and can quickly and efficiently process large quantities of cables, greatly improving production efficiency.

*High-speed operation while ensuring stability, suitable for large-scale production lines.

6. Tool adjustment and protection function

*The tool design is adjustable and can be accurately adjusted according to the outer diameter of the cable, the thickness of the insulation layer, etc., to ensure that the wire will not be damaged.

*Equipped with safety protection devices, including emergency stop switches, operating protection covers, etc., to ensure the safety of operators.

7. High durability and stability

*The equipment is made of high-quality materials and precision processing technology, and has a long service life.

*The equipment has high stability and durability, and is not prone to failure even after long-term operation, reducing maintenance costs.

8. Multifunctional design

*In addition to the conventional cable stripping function, some models of equipment may also have multiple functions such as cutting, marking, and end-capping, which improves the comprehensive application ability of the equipment.

*Different types of knives, sensors and functional modules can be selected to meet special needs.

9. Accurate control and operation

*The setting interface of the touch screen can display the stripping process, production status, working time and other data in real time, which is convenient for tracking and management.

*The automated workflow reduces human operation errors and improves overall production efficiency and product consistency.

16. Good after-sales service and support

*Provide comprehensive after-sales service, including technical support, equipment commissioning, repair and maintenance, to ensure the long-term stable operation of the equipment.

*Customized solutions can be provided according to customer needs to meet the specific requirements of different production environments.

|

Model

|

CS-8120

|

CS-8150

|

|

Conductor cross-section

|

4 – 120 mm²

|

10 – 150 mm²

|

|

Cutting length

|

1 – 99999.99 mm

|

1 – 99999.99 mm

|

|

Cutting length tolerance

|

0.002 * L (L = cutting length)

|

< 0.002 * L (L = cutting length)

|

|

Stripping length (side I)

|

1 – 800 mm

|

1 – 220 mm

|

|

Stripping length (side II)

|

1 – 400 mm

|

1 – 100 mm

|

|

Maximum diameter of conduit

|

30 mm

|

33 mm

|

|

Knife material

|

High quality imported high speed steel

|

|

|

Productivity

|

1800 pcs./h (multi-conductor cable 800 pcs./h)

|

|

|

Display mode

|

7-inch touch screen

|

|

|

Driving mode

|

Knife rest by servo motor, others by stepping motor

|

|

|

Feeding mode

|

By belts

|

|

|

Remarks

|

Special cable can be customized by sending samples

|

|

|

Dimension

|

1020*610*1150mm

|

|

Heavy Machinery: Powering large industrial equipment (e.g., CNC machines, compressors, or conveyor systems) requiring high current capacity (typically up to ~300A at 400V, depending on insulation and standards).

Motor Circuits: Supplying three-phase motors (e.g., pumps, fans) where robust power transmission is critical.

Distribution Panels: Serving as main feeder cables in factory power distribution systems.

Main Power Supply: Linking transformers to switchgear or distributing power across floors in high-rise buildings.

Data Centers: Supporting high-load backup generators or UPS systems to ensure uninterrupted power.

Shopping Malls: Powering centralized HVAC systems or large lighting arrays.

Substations: Connecting transformers to grid networks in medium-voltage (up to 1kV) setups.

Street Lighting: For high-power LED arrays or long-distance underground lighting circuits.

Tunnels/Bridges: Providing durable, high-capacity wiring in harsh environments (often armored or XLPE-insulated).

Solar Farms: Transferring aggregated DC/AC power from solar inverters to the grid.

Wind Turbines: Handling high currents from turbine generators to substations.

Shipboard Power: Used in engine rooms or deck machinery due to corrosion-resistant designs (e.g., tinned copper).

Oil Rigs: Powering drilling equipment with flame-retardant (FR) or oil-resistant insulation.

Excavators/Haul Trucks: Flexible, abrasion-resistant cables for mobile mining equipment.

Underground Wiring: Armored (SWA) or steel-reinforced cables for pit operations.

Voltage Rating: Commonly rated for 0.6/1kV (LV) or up to 35kV (HV with special insulation).

Conductor Material:

Copper: Higher conductivity (~98% IACS), ideal for compact spaces.

Aluminum: Lighter/cheaper, used where space isn’t constrained (e.g., overhead lines).

Insulation Types:

PVC: General-purpose, cost-effective.

XLPE: Heat-resistant (up to 90°C), suited for outdoor/dynamic loads.

Rubber: Flexible for movable equipment.

Protection: Armored (e.g., SWA) for mechanical stress, or unarmored for conduit use.

International: IEC 60502 (LV power cables), IEC 60228 (conductor standards).

Regional:

EU: EN 50525, HAR markings.

USA: UL 44/UL 83 (insulation standards), NEC Ampacity Tables.

UK: BS 5467 (armored cables), BS 6724 (XLPE).

Ampacity: ~240A (copper, XLPE, 40°C ambient) – varies with derating factors.

Bending Radius: ~12× cable diameter to avoid insulation damage.

Termination: Requires lugs/crimping tools for secure connections.

Balances current capacity (~300A) with manageable size/weight.

Versatile for fixed/mobile installations.

Compatible with standard cable trays/ducts.

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to sales@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions