The CS-B35 wire stripping machine is a robust and precision-engineered tool designed to streamline the processing of wires with cross-sections ranging from 1.0-35mm². Equipped with integrated cutting and stripping functions, this machine significantly enhances productivity in electrical wiring, cable harness production, and industrial assembly lines.

Functions & Features:

1. 8-wheel drive and double-sided pressure wheel design

*This machine adopts 8-wheel drive and is equipped with double-sided pressure wheels, with strong power and high-precision transmission system. Through 8-wheel drive, it can provide more uniform wire delivery and stable stripping effect.

*The double-sided pressure wheel design ensures that the cable will not be displaced or deflected during the stripping process, improving processing accuracy and stability.

*The belt feeding system ensures that the cable surface is not damaged, and can smoothly feed the cable to improve processing efficiency. This system is widely used in various fields, such as military, medical, communication, power cable, sheathed wire, soft and hard wire processing.

2. Automatic adjustment of the inlet and outlet wheels

*The clamping force of the inlet and outlet wheels can be directly adjusted by the program, without manually adjusting the wheel pressure, reducing manual operation errors and improving work efficiency.

*Automatic lifting function of the outlet wheel: When stripping the wire head, the outlet wheel can be automatically lifted up to avoid collision with the wire, thereby increasing the length range of wire head stripping.

*The lifting height of the outlet wheel can also be set by the program, which is convenient for adjusting the stripping area according to different cable specifications to ensure efficient and accurate processing.

3. Color touch screen operation interface

*The color touch screen operation interface is intuitive and clear, easy to operate, and the parameters are clearly displayed. Users only need simple training to quickly get started.

*The touch screen interface makes the operation more user-friendly, and the parameter setting and adjustment are more flexible. Users can directly view parameters such as stripping length and speed on the screen.

*Three-layer stripping program: The device supports three-layer stripping, or when the stripping length is long, the stripping process can be completed in up to three times. This function can improve the stripping accuracy of long cables and ensure that each layer of stripping can be done accurately.

Provide 200 sets of program memory function, which can store the processing parameters of different wires. Users can quickly switch different processing programs according to needs, simplifying operations and improving production efficiency.

4. Additional functions and customized options

*Wire splitting jigs can be installed: By installing wire splitting jigs, the wire splitting requirements of specific cables can be met and the processing accuracy can be improved.

* Scratching jig: You can install a scratching jig to perform precise slashing operations on some special cables.

* Inkjet printer: If you need to mark or print on the stripped cable, the device supports the installation of an inkjet printer to facilitate the printing of batch identification, production date and other information.

| Machine Model | CS-B35 |

| Wire range | 1.5-35mm² |

| Cutting Length | 0-100m |

| Stripping Length | Head 0-250mm; Tail 0-120mm |

| Conduit Diameter | φ16mm |

| Drive Method | 8wheels drive |

| power | 650W |

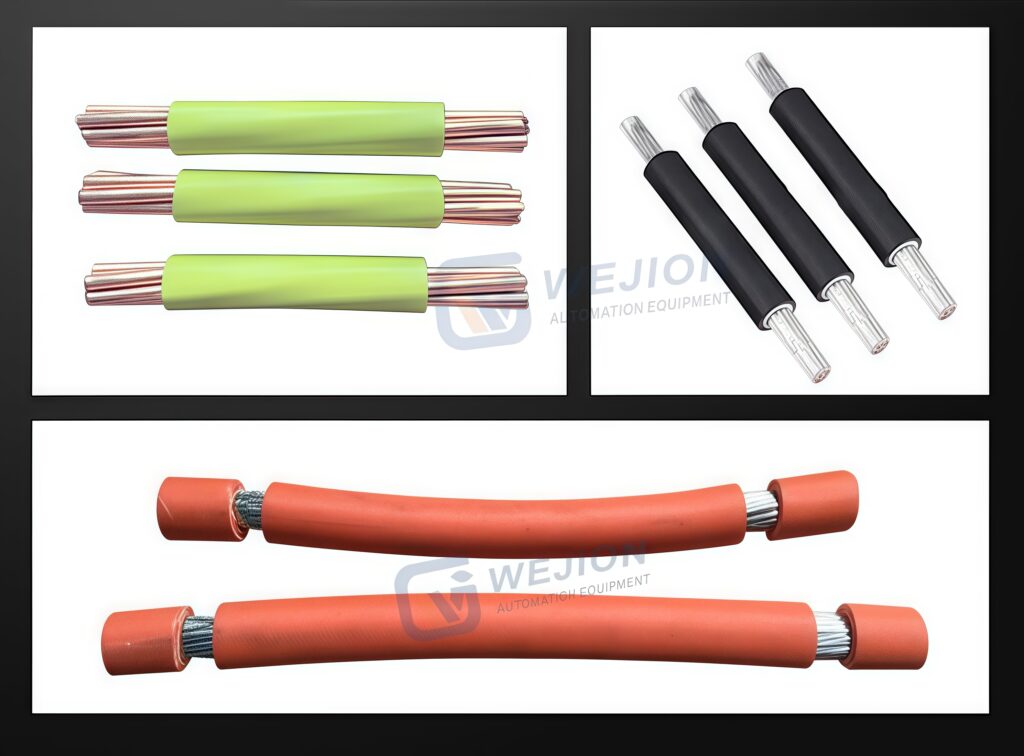

| Wire types | Multi – strand copper wire, coaxial cable, sheath wire, etc |

| Blade material | Imported high speed steel |

| Production Rate | 1500-2500pcs/h |

| Display Screen | 7 inch touch screen |

| Wire Feed Method | Belt feeding wire, no indentation on cable |

| Memory function | Up to 100 groups of programs can be stored |

| Weight | 70kg |

| Dimensions | 56*52*45cm |

| Machine Model | CS-B35 |

|---|---|

| Wire range | 1.0-35mm² |

| Cutting Length | 0-100m |

| Stripping Length | Head 0-250mm; Tail 0-120mm |

| Conduit Diameter | φ16mm |

| Drive Method | 8wheels drive |

| power | 650W |

| Wire types | Multi – strand copper wire, coaxial cable, sheath wire, etc |

| Blade material | Imported high speed steel |

| Production Rate | 1500-2500pcs/h |

| Display Screen | 7 inch touch screen |

| Wire Feed Method | Belt feeding wire, no indentation on cable |

| Memory function | Up to 100 groups of programs can be stored |

| Weight | 78kg |

| Dimensions | 56*52*45cm |

Motor Power Supply: Suitable for three-phase motors (e.g., 15–30 kW) in machinery, pumps, or conveyor systems.

Control Panels: Feeder lines for distribution boards or industrial control cabinets.

Main Circuit Wiring: As sub-main lines in residential/commercial buildings (e.g., from meter boxes to distribution panels).

High-Power Outlets: For heavy-duty equipment like commercial ovens, HVAC systems, or large workshop tools.

Solar/Wind Farms: Connecting solar arrays to inverters or wind turbines to charge controllers (handling DC or AC currents).

Street Lighting: Power supply lines for high-lumen LED or HID streetlights.

Underground Cabling: Armored variants (e.g., XLPE-insulated) for buried power distribution.

Construction Sites: Powering heavy machinery (e.g., cranes, cement mixers) via portable cables (often rubber-insulated for flexibility).

EV Charging Stations: For AC Level 2 chargers (up to 22 kW) or DC fast charger auxiliary circuits.

Railway Systems: Auxiliary power lines for signaling or station equipment.

Ship Wiring: Engine room circuits or deck machinery connections (using tinned copper for corrosion resistance).

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to sales@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions