The CS-S16 is a high-precision, automated device designed for efficiently stripping and cutting wires, primarily used in electrical, automotive, and electronic manufacturing industries. It supports wires with a cross-sectional area 0.75-16 mm² (AWG 6) and integrates cutting, stripping, and stripping length adjustment functions to enhance production efficiency.

CS-S16 fully automatic wire stripping machine can greatly improve the processing efficiency of wires and cables and ensure the processing quality through the automated and high-precision stripping function. It is easy to operate, safe and reliable, and highly efficient. It is suitable for various industrial fields that require efficient stripping, especially for enterprises that produce wires and cables in large quantities. With the improvement of industrial automation, the application prospects of this equipment in modern production lines are broad.

Function:

1. Fully automatic operation:

* Automatic feeding, stripping and cutting, the operation process requires almost no human intervention.

* The user only needs to set the stripping length, depth and stripping speed, and the machine can automatically complete the entire stripping process.

2. Precise stripping:

* It can accurately control the stripping length and stripping depth to avoid damaging the wire or insulation layer and ensure the quality of the wire.

* The stripping process can be automatically adjusted according to the wire specifications to adapt to 16 square cables and other specifications below.

3. Efficient production:

* The fully automatic operating system can efficiently and continuously complete the wire stripping work, which is suitable for mass production.

* In the large-scale production process, the equipment can maintain stable operation, reduce the errors caused by manual operation, and improve production efficiency.

4. Multifunctional stripping:

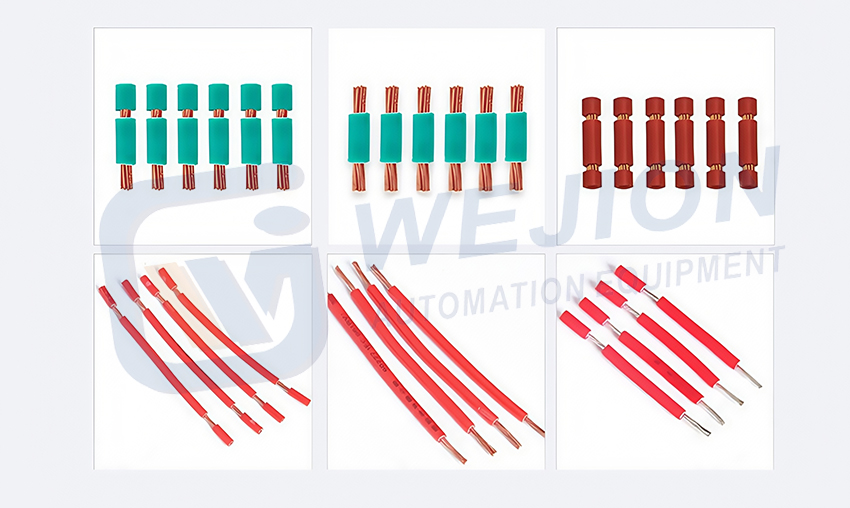

*Supports multiple stripping methods such as single-head stripping, double-head stripping, and circular stripping, and can handle different types of cables.

*The stripping length and number of stripping heads can be adjusted as needed to meet different application requirements.

5. Precise tool control:

*The use of high-precision tools can accurately strip the cable sheath without damaging the conductor.

*The tools can be replaced quickly and have a long service life, reducing maintenance costs.

Features:

1. High-precision stripping:

*The machine can accurately control the stripping length and depth, which not only ensures that the cable is stripped evenly and neatly, but also avoids the risk of damaging the wire or insulation layer, ensuring that the stripped cable is suitable for subsequent connection and use.

2. High degree of automation:

*The equipment has a high degree of automation and automatically completes the feeding, cutting, stripping and other processes of the cable. It reduces manual operations and improves production efficiency, especially suitable for mass production of cables.

3. Easy to operate:

* Equipped with a touch screen display and operation interface, users can easily set various parameters such as stripping length, speed, depth, etc. The operation is simple and intuitive, and even operators without professional experience can easily get started.

* The equipment runs stably and has real-time monitoring function to ensure the smooth progress of the production process.

4. Wide range of applications:

* Although the main design of the machine is suitable for 16 square wires, it can usually support stripping wires below 16 squares. By adjusting the parameters, it can handle wires of different specifications.

* At the same time, it can adapt to cables of different materials, including copper wire, aluminum wire and its alloy wire.

5. High speed and efficiency:

* The fully automatic wire stripping machine has a fast stripping speed, and can usually complete the processing of a large number of wires in a short time, and can efficiently cope with large-scale production tasks.

* The high efficiency of the machine not only saves time, but also reduces the risk of manual misoperation during the production process.

6. High stability and safety:

* The equipment uses high-quality steel and precision mechanical parts to ensure the stability of the machine and durability in long-term use.

*Equipped with multiple safety protection devices, such as emergency stop button, electrical overload protection, tool protection, etc., to ensure the safety of operators.

7. Cost saving:

*Automated operation reduces labor costs, while also improving production efficiency and production consistency, helping companies reduce manufacturing costs.

| Model | CS-S16 |

| Available Wire Size | 0.75-16mm2 |

| Conductor Cross-Section | AWG18-AWG5 |

| Stripping Length | 0-45mm |

| Cutting Length | 1-9999.9mm |

| Cutting Length Tolerances | ±(0.002*L)mm |

| Intermediate Stripping | Max 15 sections |

| Conduit Diameter | φ6-14mm |

| Production Rate | 1000-3000pcs/h |

| Wire Feed Method | Roller feeding |

| Drive Method | 4 wheels drive |

| Display Screen | Chinese / English LCD Screen |

| Power Supply | 220V/110V |

| Power | 600W |

| Weight | 48kg |

| Dimensions | 51*51*41.5cm |

| Model | CS-S16 |

|---|---|

| Available Wire Size | 0.75-16mm2 |

| Conductor Cross-Section | AWG18-AWG5 |

| Stripping Length | 0-45mm |

| Cutting Length | 1-9999.9mm |

| Cutting Length Tolerances | ±(0.002*L)mm |

| Intermediate Stripping | Max 15 sections |

| Conduit Diameter | φ6-14mm |

| Production Rate | 1000-3000pcs/h |

| Wire Feed Method | Roller feeding |

| Display Screen | Chinese / English LCD Screen |

| Power Supply | 220V/110V |

| Power | 600W |

| Weight | 48kg |

| Dimensions | 51*51*41.5cm |

Power Cable Termination – Strips and cuts 16 mm² wires used in circuit breakers, distribution boards, and switchgear.

Substation Wiring – Prepares high-current cables for transformers, busbars, and grounding systems.

Industrial Power Lines – Processes armored cables (SWA), XLPE, and PVC-insulated wires for factories and plants.

Solar Farm Wiring – Handles PV cables (4-16 mm²) for solar panel arrays and inverters.

Wind Turbine Power Cables – Strips thick conductors in wind energy transmission systems.

Battery Energy Storage (BESS) – Prepares lithium-ion battery busbars and high-capacity wiring.

Motor & Pump Wiring – Processes 16 mm² motor leads for industrial pumps, compressors, and CNC machines.

Mining & Construction Equipment – Used in heavy-duty cable harnesses for excavators, cranes, and drilling rigs.

Welding Machine Cables – Prepares high-flexibility welding leads for industrial welding systems.

EV Charging Stations – Strips thick DC fast-charging cables (16 mm² and above).

Commercial Vehicle Wiring – Used in trucks, buses, and agricultural machinery for high-power circuits.

Battery Pack Assembly – Processes high-voltage battery interconnects in electric cars.

Shipboard Wiring – Handles marine-grade cables for navigation, propulsion, and power distribution.

Oil & Gas Offshore Rigs – Prepares flame-retardant and oil-resistant cables for harsh environments.

Locomotive Wiring – Strips 16 mm² power and control cables in trains and metros.

Railway Signaling & Electrification – Used in overhead catenary systems (OCS) and track circuits.

Server Farm Power Distribution – Processes 16 mm² copper busbars and backup power wiring.

5G Tower Cabling – Prepares high-current DC power lines for telecom base stations.

Commercial HVAC Systems – Strips thick power cables for chillers, VRF systems, and industrial cooling.

Building Power Lines – Used in high-rise electrical wiring for elevators and backup generators.

Military Vehicle Wiring – Processes armored cables for tanks, armored vehicles, and radar systems.

Aircraft Ground Power Units (GPU) – Prepares high-amperage ground power cables.

Industrial Electricians – Used for quick stripping of 16 mm² cables during maintenance.

Heavy Equipment Repair – Essential for rewiring mining trucks, bulldozers, and generators.

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to sales@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions