The T – 23 is an upgraded pneumatic – electric wire processing machine. It twists 1 – 16mm² wires, brushes 0.1 – 10mm wires, and strips wires within 6mm outer diameter. With automatic clamping and adjustable features.

Efficient Wire Twisting

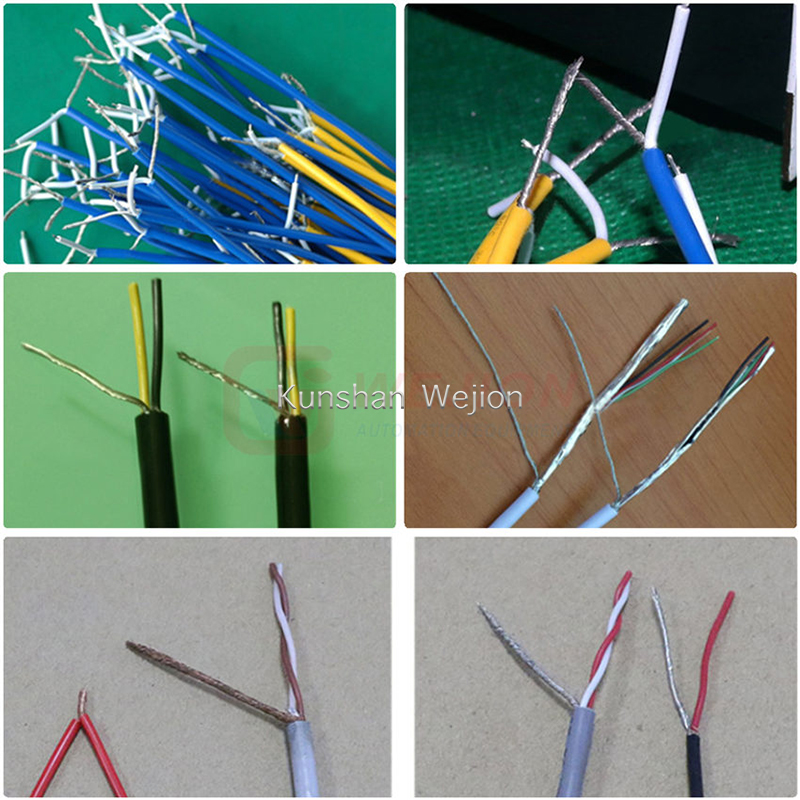

The T – 23 is capable of twisting various types of wires such as ground wires, braided wires, and isolation wires within the size range of 1 – 16mm². It replaces manual wire twisting, ensuring consistent and precise twists with a twist length ranging from 5 – 80mm. This function is crucial for creating secure electrical connections in different applications, eliminating the need for laborious manual operations.

Automatic Clamping and Operation

The machine features pneumatically controlled clamping hands that open automatically when the air source is connected. During operation, users simply place the wire in the designated area and activate the foot switch to complete the twisting process. This automated operation simplifies the wire – twisting task and increases production efficiency, making it suitable for both small – scale and large – scale production environments.

Versatile Brushing Function

With a 12V, 3000 – rpm brush motor, the T – 23 can handle wires with a diameter between 0.1 – 10mm. It has the ability to brush the shielded mesh of wires, spreading it to one side before twisting. The brush can also handle stripping lengths of 1 – 60mm (extendable to 80 – 10mm depending on the wire material). This brushing function is essential for preparing wires with shielded meshes for subsequent twisting, ensuring better electrical insulation and signal transmission.

Wire Stripping and Adjustability

The machine offers a wire stripping function for wires with an outer diameter of 6mm or less. The brush wheel spacing is adjustable, and the speed of the stripping wheels can be adjusted steplessly, controlled by a separate switch. This adjustability allows for precise stripping of wires, adapting to different wire types and processing requirements. It ensures that the wire stripping process is efficient and customized according to the specific needs of the wire being processed.

User – Friendly Design

The automatic clamping hands are designed to be exposed, making it extremely easy to place dispersed copper wires. The elastic wire clamping mechanism can accommodate different wire diameters without the need for adjustment, reducing the complexity of operation. The addition of an automatic wire – pulling device shortens the training time for new operators, making the machine accessible to a wider range of users.

Adjustable Chuck and Clamping Force

The size of the chuck opening can be adjusted by loosening the chuck spindle screw inside the machine, moving the entire chuck towards the motor, and tightening the spindle screw. The clamping force of the chuck can be adjusted by adding 5 to 6 springs, providing flexibility to handle different wire sizes and ensure a secure grip during the twisting process. This adjustable chuck and clamping force feature enhances the machine’s versatility and performance.

Power and Compatibility

With a power consumption of 10W and compatibility with both 220V and 110V power supplies at frequencies of 50 – 60Hz, the T – 23 is energy – efficient and suitable for use in different regions. Its compact size (343221cm) and weight of 15kgs make it easy to install and move, fitting into various workspaces. The air pressure requirement of 1.5 – 2.5kgs/cm further ensures stable operation during the wire – processing tasks.

Enhanced Wire Processing Capability

The combination of wire twisting, brushing, and stripping functions in one machine makes the T – 23 a comprehensive solution for wire processing. It can handle a wide range of wire types and sizes, providing a one – stop solution for various wire – related tasks. The ability to handle different shielded mesh densities and wire stripping lengths makes it suitable for diverse applications in industries such as electronics manufacturing, electrical equipment production, and telecommunications.

| Model | T-23 |

| Air pressure | 1.5-2.5kgs/cm |

| Power supply | 220V/110V 50-60Hz |

| Power | 10W |

| Twist length | 5-80mm |

| Wire size | 1-16mm² |

| Size | 34*32*21cm |

| Weight | 15kgs |

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to sales@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions